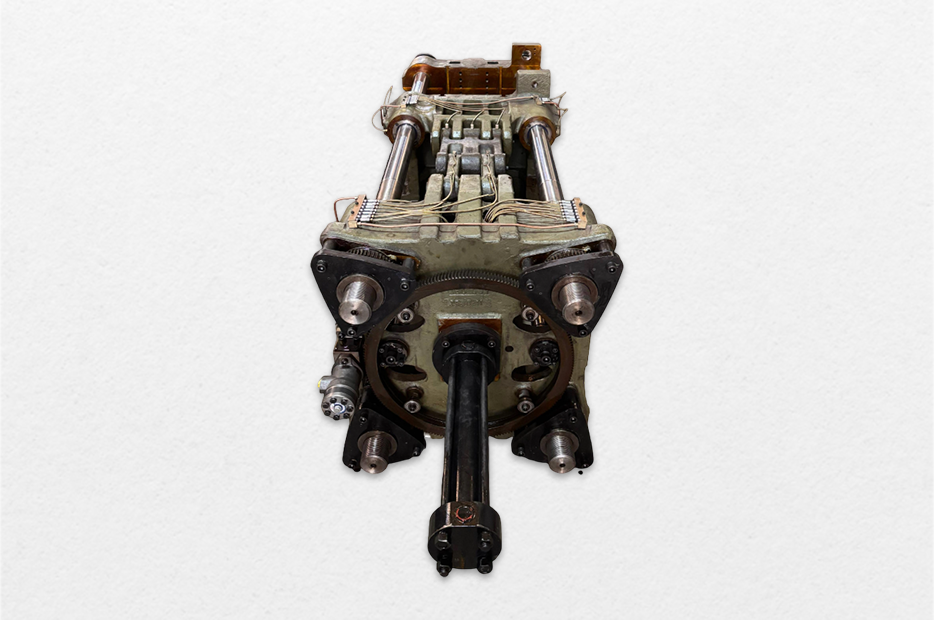

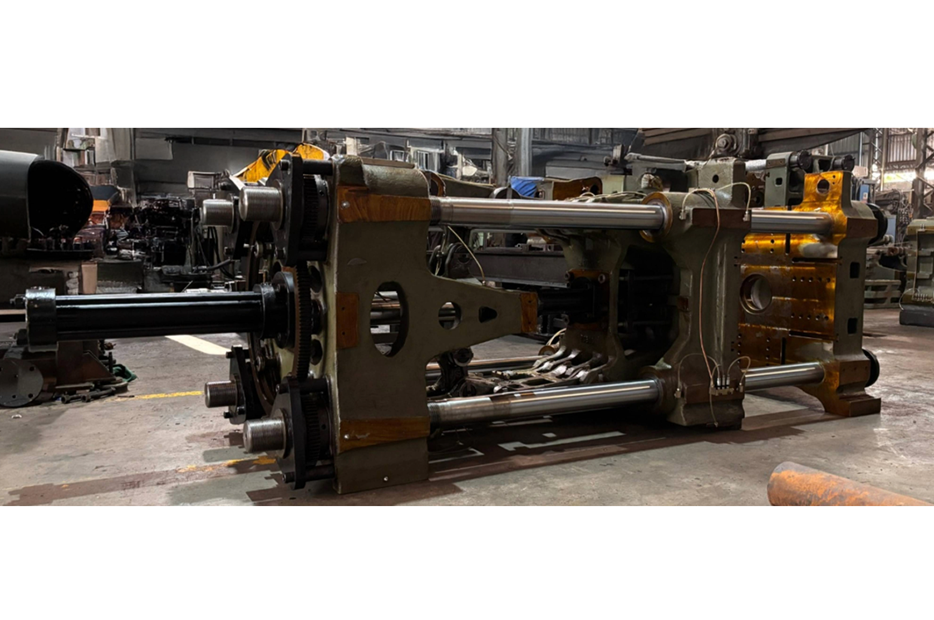

HEATTRANS CLAMPING UNIT (90–500 TON RANGE)

Heattrans Clamping Units are engineered with precision machining, certified metallurgy, high-rigidity platens, and maintenance-friendly mechanisms, delivering stable performance in long production cycles with near-zero downtime. You get repeatability, long service life, and superior mold protection—with support and spares easily accessible.

Heattrans Advantage

- High-quality casting & precision machining ensures zero vibration and accurate mold alignment

- Reliable and consistent design for stable, high-volume production

- Defect-free, certified metallurgy for structural strength

- Hydraulic cylinders with no welded joints → last longer under heavy load

- T-slot platens for faster mold setup

- Special alloy tie bars & treated locking pins offer exceptional durability

- Spares always available for minimal downtime

What Heattrans Supplies (Complete Package)

You receive a fully loaded, ready-to-integrate clamping system with:

- Three precision-machined platens with standard tie-bar length and moving plate shoe

- High-strength toggle assembly with steel bushes & pins

- Lubrication pipeline for grease/oil (pump optional)

- China-made orbital hydro motor for accurate mold height adjustment

- Ejector cylinder with plate & rod

- Heavy-duty clamping cylinder

- Premium Upgrades Included:

- T-Slot platens

- Specially treated locking pin & bush

- Special alloy tie bars

This eliminates dependency on external suppliers — reducing commissioning time and avoiding compatibility issues.

Mold Clamping Unit Specifications :

| Model | HT-90 | HT-120 | HT-160 | HT-200 | HT-260 | HT-350 | HT-450 | HT-500 | |

|---|---|---|---|---|---|---|---|---|---|

| Ton | x 10 KN | 90 | 120 | 160 | 200 | 260 | 350 | 450 | 500 |

| Tie bar Distance | mm | 370 x 370 | 430 x 430 | 470 x 470 | 520 x 520 | 580 x 580 | 680 x 680 | 780 x 780 | 830 x 830 |

| Mold Opening Stroke | mm | 350 | 390 | 450 | 480 | 550 | 640 | 740 | 835 |

| Mold Height Min/Max | mm | 150-380 | 150-450 | 160-500 | 200-550 | 200-600 | 200-700 | 250-820 | 300-850 |

| Maximum Day Light | mm | 730 | 840 | 950 | 1030 | 1150 | 1340 | 1560 | 1685 |

| Ejector Stroke | mm | 90 | 120 | 140 | 160 | 180 | 200 | 150 | 250 |

| Ejector Force | KN | 35 | 50 | 50 | 60 | 60 | 80 | 125 | 150 |

| Tiebar Dia | mm | 65 | 75 | 80 | 90 | 100 | 120 | 130 | 140 |

| Drill / T-Slot | - | T-Slot | T-Slot | T-Slot | T-Slot | T-Slot | T-Slot | T-Slot | T-Slot |

| Platten Size | mm | 560 x 560 | 640 x 640 | 690 x 690 | 770 x 770 | 845 x 845 | 980 x 980 | 1150 x 1150 | 1200 x 1200 |